Table of Contents

- Executive Summary: Key Trends and Market Drivers in 2025

- Technology Overview: Fundamentals of Cryogenic Fuel Gasification

- Competitive Landscape: Leading Companies and Emerging Players

- Breakthrough Innovations: Recent Advances and Patents

- Global Market Forecasts Through 2030: Growth Hotspots and Projections

- End-Use Applications: Energy, Transportation, and Industrial Impact

- Regulatory Environment and Industry Standards (eg. asme.org, ieee.org)

- Supply Chain and Infrastructure Challenges

- Sustainability and Environmental Impact Analysis

- Future Outlook: Investment Opportunities and Strategic Recommendations

- Sources & References

Executive Summary: Key Trends and Market Drivers in 2025

Cryogenic fuel gasification systems are experiencing a surge in strategic relevance and commercial deployment as the global energy sector accelerates its transition to low-carbon and alternative fuels. These systems—vital for converting liquefied fuels such as LNG and liquid hydrogen into usable gaseous forms—are increasingly central to industrial decarbonization, power generation, and mobility applications. In 2025, several key trends and market drivers are shaping the trajectory of this sector.

- Hydrogen Economy Expansion: The rapidly growing interest in hydrogen as a clean energy vector is a primary catalyst. Governments and industry leaders have announced significant investments in cryogenic hydrogen infrastructure, with projects like Air Liquide’s recent unveiling of advanced hydrogen liquefaction and regasification facilities in 2024 setting the stage for further deployment in 2025.

- LNG Market Momentum: Liquefied Natural Gas (LNG) remains a core application, with demand driven by fuel switching in power and maritime sectors. Technological advancements, such as the high-efficiency gasification modules developed by Linde, are enabling more flexible, scalable, and energy-efficient regasification terminals, supporting new projects scheduled for commissioning through 2025 and beyond.

- Environmental Regulation and Decarbonization Policies: Stricter emissions standards in regions like the EU and East Asia are prompting utilities and heavy industry to invest in cryogenic gasification as a cleaner alternative to traditional combustion systems. Companies such as Shell are actively expanding LNG regasification capacity to serve these regulatory needs.

- Integration with Renewable Energy Systems: The ability to store and dispatch renewable-derived hydrogen and bio-LNG in cryogenic form is increasingly valued for grid balancing and seasonal storage. Players including Siemens Energy are leading initiatives to integrate cryogenic gasification into hybrid energy systems, with several demonstration plants expected to reach operational status in 2025.

Looking forward, the outlook for cryogenic fuel gasification systems in 2025 is characterized by robust investment, technological innovation, and expanding end-use applications. Industry leaders are leveraging proprietary system designs to boost efficiency and reduce operational costs, while public sector funding and policy incentives continue to underpin market growth. As both hydrogen and LNG infrastructure mature, the sector is positioned for sustained expansion through the latter half of the decade.

Technology Overview: Fundamentals of Cryogenic Fuel Gasification

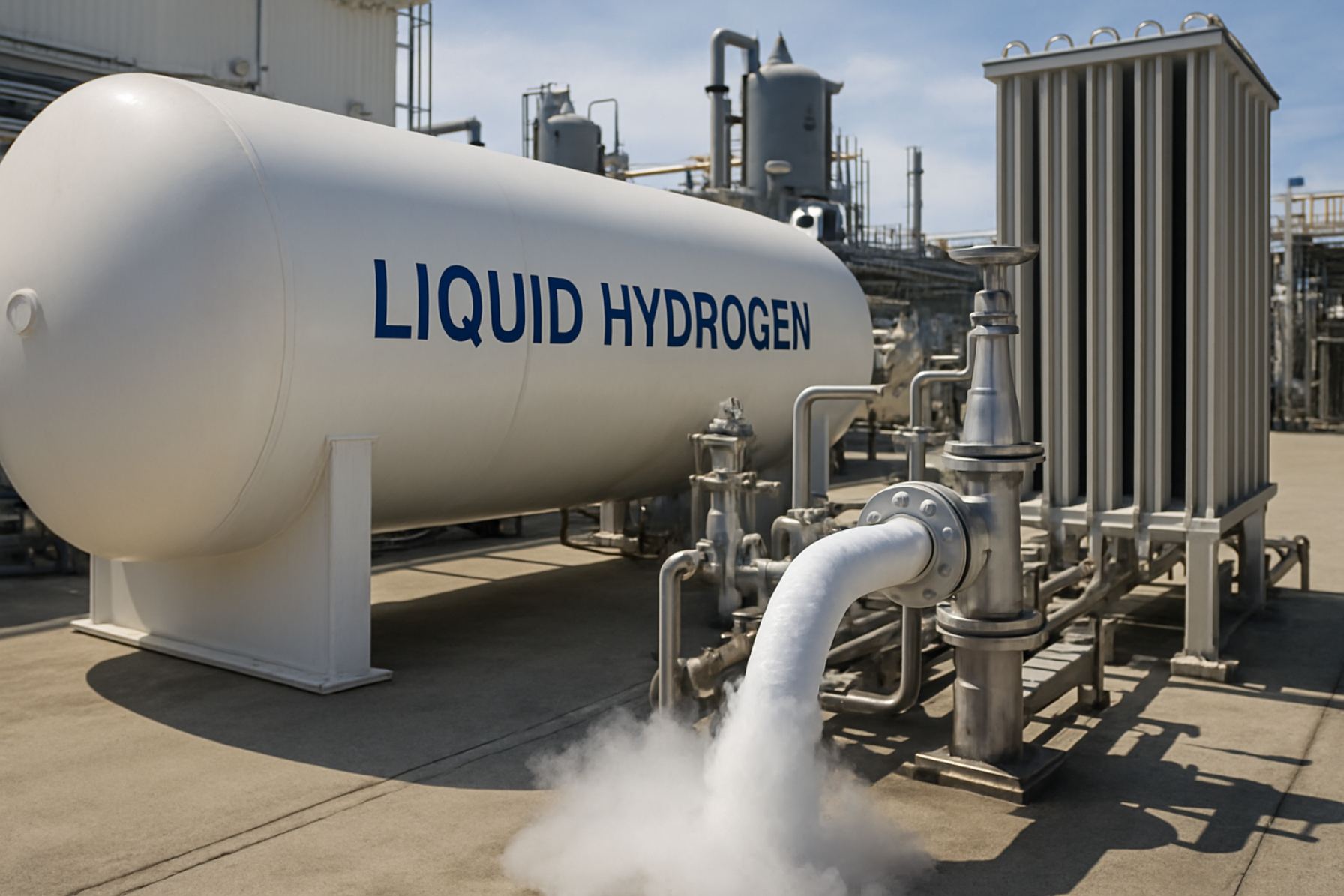

Cryogenic fuel gasification systems represent a cornerstone technology for advancing the use of low-carbon and high-energy-density fuels, particularly in sectors such as power generation, chemicals, and transportation. These systems leverage extremely low temperatures to handle, process, and convert fuels such as liquefied natural gas (LNG), liquid hydrogen, and other cryogenic hydrocarbons into gaseous forms suitable for combustion or further chemical synthesis. The process requires precise thermal management, robust containment technologies, and advanced materials to ensure safe and efficient operation.

As of 2025, the technology landscape is shaped by increasing global investments in LNG re-gasification and hydrogen liquefaction infrastructure. For LNG, cryogenic gasification systems are typically employed at import terminals, where LNG is vaporized using heat exchangers—most commonly open rack vaporizers (ORV), seawater vaporizers, or submerged combustion vaporizers. Companies such as Air Products and Chemicals, Inc. and Mitsubishi Power have developed large-scale cryogenic heat exchanger technologies capable of handling flows in excess of 1,000 tons per hour, with efficiency gains achieved through improved alloy design and advanced thermal integration.

The outlook for hydrogen cryogenic gasification is particularly promising, as hydrogen liquefaction and regasification are critical for enabling long-distance transport and large-scale storage. By 2025, pilot projects led by Air Liquide and Linde plc are demonstrating integrated cryogenic hydrogen gasification systems for both industrial and mobility applications. These systems must contend with hydrogen’s unique material embrittlement and boil-off challenges, leading to innovations in cryogenic pump and vaporizer design.

- Process Fundamentals: Cryogenic gasification involves transferring heat to liquefied fuel to induce phase change (liquid to gas), typically through indirect heat exchangers. The design must minimize exergy losses and ensure complete vaporization to prevent cold spots and potential safety hazards.

- System Integration: Modern gasification systems are increasingly integrated with waste heat recovery units or renewable energy sources to lower operational carbon footprints. For instance, Shell is piloting hybrid systems that use waste heat from adjacent industrial processes for LNG regasification, reducing reliance on direct combustion vaporizers.

- Digitalization and Automation: Digital monitoring, predictive maintenance, and advanced control systems are being adopted to optimize performance and enhance safety. Siemens Energy offers solutions for real-time process monitoring and energy management in cryogenic facilities.

Over the next few years, further advances are expected in modularization, improved heat exchanger efficiency, and integration with carbon capture systems. As global demand for clean fuels grows, cryogenic fuel gasification systems will continue to play a pivotal role in the energy transition, enabling flexible, scalable, and secure energy infrastructure.

Competitive Landscape: Leading Companies and Emerging Players

The competitive landscape of cryogenic fuel gasification systems in 2025 is marked by a convergence of established industrial gas giants and innovative engineering firms, all seeking to meet the rising demand for clean energy vectors such as hydrogen and synthetic fuels. The sector is characterized by advancements in liquefaction, gasification, and process integration, with significant activity in project deployment and technology scaling.

Among the global leaders, Air Liquide and Linde continue to dominate with extensive portfolios in cryogenic technologies and integrated gasification solutions. Both companies are actively expanding their capacities for hydrogen and liquefied natural gas (LNG) production, leveraging proprietary cryogenic air separation and gasification technologies. For example, Air Liquide has announced the construction of new hydrogen production units utilizing advanced cryogenic purification and gasification, targeting both industrial and mobility markets.

Air Products, another major player, is aggressively investing in large-scale initiatives, such as the NEOM Green Hydrogen Project in Saudi Arabia, which employs cryogenic gasification and liquefaction to produce and export green hydrogen in the form of ammonia. These projects underscore the company’s expertise in integrating cryogenic processes with renewable feedstocks and underline a shift toward sustainable fuels in global supply chains.

On the technology supply side, KBR and Shell are prominent for their proprietary gasification technologies, including cryogenic systems for both coal and biomass. KBR’s Advanced Gasification Technology is being implemented in new projects targeting low-carbon hydrogen, while Shell continues to license its Shell Coal Gasification Process (SCGP), integrating cryogenic air separation for syngas production.

Emerging players are also making an impact, particularly those specializing in modular and small-scale cryogenic gasification systems. Companies such as Hyzon Motors are developing integrated solutions for distributed hydrogen fueling, utilizing compact cryogenic gasification units. Meanwhile, engineering startups are collaborating with established gas companies to pilot novel cryogenic gasification approaches, aiming to improve energy efficiency and reduce capital costs.

Looking ahead to the next few years, the competitive landscape is likely to intensify as government policies and decarbonization targets accelerate demand for cryogenic gasification solutions. Companies are expected to focus on scaling up demonstration plants, refining process integration, and expanding partnerships to address emerging markets in Asia, Europe, and North America. As technology matures, the sector will likely see further differentiation based on efficiency, scalability, and lifecycle emissions.

Breakthrough Innovations: Recent Advances and Patents

Cryogenic fuel gasification systems are experiencing a wave of innovation as the energy sector seeks more efficient and cleaner fuel conversion technologies. Recent advances focus on optimizing the handling of liquefied natural gas (LNG) and liquid hydrogen (LH2), as these fuels play an increasingly pivotal role in decarbonizing power generation and heavy transport. In 2025, leading manufacturers and energy organizations have accelerated the development and patenting of novel cryogenic gasification methods, targeting lower energy consumption, enhanced safety, and integration with renewable energy sources.

One of the major breakthroughs in 2025 has been the commercialization of integrated cryogenic gasification modules that combine cold energy recovery with advanced heat exchanger designs. For example, Linde has introduced modular cryogenic gasification skids that utilize proprietary plate-fin heat exchangers and turboexpanders, significantly reducing boil-off losses and improving overall energy efficiency in LNG regasification plants. Similarly, Air Products and Chemicals, Inc. has patented a hybrid gasification process that leverages excess cold from LNG to pre-cool feedstock, resulting in up to 12% energy savings compared to traditional gasification techniques.

Hydrogen is also at the forefront of cryogenic gasification innovation. In early 2025, Siemens Energy filed patents for a cryogenic hydrogen gasification system that integrates high-temperature electrolysis and cold energy recovery, enabling rapid ramp-up for grid-balancing applications. This approach not only enhances system flexibility but also addresses key challenges in storage and transportation of liquid hydrogen. Moreover, IHI Corporation has demonstrated a pilot-scale LH2 gasification module featuring advanced insulation and boil-off gas management, which has been adopted in Japan’s first LH2-to-power demonstration project.

Looking ahead, the outlook for cryogenic fuel gasification systems is robust, with several large-scale demonstration projects scheduled for commissioning by 2027. Industry consortia led by Shell and TotalEnergies are investing in next-generation LNG and hydrogen regasification terminals that incorporate patented cryogenic gasification and cold energy recovery technologies. These facilities are expected to set new benchmarks for efficiency and environmental performance, supporting the broader transition to low-carbon fuels.

Overall, the period from 2025 onward is expected to see continued patent activity, with a focus on digital integration, modularity, and lifecycle emissions reduction. As global demand for clean energy carriers grows, cryogenic fuel gasification systems will remain a critical area for technological advancement and commercial deployment.

Global Market Forecasts Through 2030: Growth Hotspots and Projections

The global market for cryogenic fuel gasification systems is poised for significant expansion through 2030, driven by accelerating adoption in energy, transport, and heavy industry sectors. As of 2025, surging investment in hydrogen and liquefied natural gas (LNG) infrastructure is a primary catalyst for market growth. Key economies in Asia-Pacific, Europe, and North America are prioritizing cryogenic solutions to meet decarbonization targets and enhance energy security.

In Asia-Pacific, China and Japan are at the forefront. China’s 2025 roadmap includes rapid deployment of cryogenic hydrogen fueling stations and LNG terminals, supported by major industry players such as Sinopec and CNOOC. Japan’s government, in partnership with companies like IHI Corporation, is expanding its hydrogen supply chain, with cryogenic gasification systems integral to new import terminals and distribution networks.

In Europe, the European Union’s “Fit for 55” package is accelerating the installation of cryogenic gasification infrastructure for both LNG and hydrogen. Companies such as Linde and Air Liquide are reporting major new contracts for large-scale facilities, particularly in Germany, France, and the Netherlands, where hydrogen hubs and LNG regasification projects are under development through 2027. The EU’s ambition to import 10 million tonnes of renewable hydrogen by 2030 underscores the need for robust cryogenic gasification capabilities.

North America is also experiencing strong momentum, with the United States investing in hydrogen supply chains and expanding its LNG export capacity. Chart Industries and Air Products are scaling up manufacturing of cryogenic equipment for new liquefaction and regasification plants. In 2025, several multi-billion-dollar projects are underway along the Gulf Coast, aiming to serve both domestic demand and international markets.

By 2030, the global installed base of cryogenic fuel gasification systems is projected to more than double from 2024 levels, with the fastest growth expected in regions with aggressive clean energy policies and infrastructure investment. Technological advancements—such as improved heat integration and higher-efficiency cold energy recovery—are anticipated to further reduce costs and improve system performance. Continued collaboration between governments, technology providers, and end-users will shape the outlook, with major growth hotspots centered in East Asia, Western Europe, and North America.

End-Use Applications: Energy, Transportation, and Industrial Impact

Cryogenic fuel gasification systems are gaining significant traction as a core technology supporting the decarbonization of critical sectors such as energy production, transportation, and industry. As of 2025, these systems—which convert cryogenically stored fuels like liquefied natural gas (LNG), liquid hydrogen, and other low-carbon liquids into gaseous fuels—are being rapidly integrated into projects aiming to reduce greenhouse gas emissions and increase operational efficiency.

In the energy sector, the adoption of cryogenic gasification is closely tied to the growing use of LNG and hydrogen as transitional and clean energy sources. Utilities and independent power producers are deploying these systems to enable flexible, low-emission power generation. For instance, GE Vernova is actively developing hydrogen-ready gas turbines that rely on onsite gasification of cryogenic hydrogen, facilitating the transition from natural gas to hydrogen blending and, eventually, pure hydrogen operation. Similarly, Siemens Energy is supporting power plants with integrated gasification systems to handle both LNG and liquid hydrogen, aiming for higher fuel flexibility and reduced carbon footprints.

The transportation sector is witnessing a surge in the deployment of cryogenic gasification, particularly for heavy-duty and marine applications. With the International Maritime Organization’s stricter emissions regulations taking effect, major shipbuilders are retrofitting fleets to operate on gasified LNG and, increasingly, liquid hydrogen. Wärtsilä has delivered advanced gasification modules that enable marine engines to switch seamlessly between LNG and hydrogen, supporting cleaner shipping operations. In rail transport, Siemens Mobility and others are piloting hydrogen-powered trains using onboard cryogenic gasification, with commercial rollout targeted for 2025–2027.

For industrial users, especially those in steel, chemicals, and cement, cryogenic gasification is becoming a linchpin for fuel switching and emissions abatement. Industrial gas suppliers like Air Liquide and Linde are installing modular cryogenic gasification plants at customer sites, enabling processes to utilize gasified hydrogen or syngas instead of coal or oil. These systems not only support direct emission reductions but also facilitate the capture and utilization of byproduct CO2.

Looking ahead to the next few years, the market outlook for cryogenic fuel gasification systems remains robust. Ongoing investment in hydrogen and LNG infrastructure, supported by government incentives and industrial decarbonization targets, is expected to accelerate system deployments. Key technology trends include further efficiency improvements, digital integration for remote monitoring, and the expansion of modular, transportable gasification units suitable for distributed applications. With cross-sectoral demand on the rise, cryogenic gasification will continue to play a pivotal role in the global energy transition through 2030 and beyond.

Regulatory Environment and Industry Standards (eg. asme.org, ieee.org)

The regulatory environment and industry standards surrounding cryogenic fuel gasification systems are evolving rapidly in 2025, driven by increased global deployment of low-carbon fuels such as liquefied natural gas (LNG) and emerging interests in liquid hydrogen. Compliance with robust engineering, safety, and environmental standards is essential for manufacturers and operators in this high-stakes sector.

The American Society of Mechanical Engineers (ASME) continues to play a pivotal role, with its Boiler and Pressure Vessel Code (BPVC) and B31 series for piping systems being foundational requirements for the design, material selection, and inspection of cryogenic components. ASME’s Section VIII (Pressure Vessels) and B31.3 (Process Piping) standards are being updated in 2025 to address the unique stresses and fracture mechanics relevant to cryogenic temperatures, especially as hydrogen and LNG infrastructure expands.

The American Petroleum Institute (API) has reinforced its standards for LNG and cryogenic gas facilities, specifically API 625 (Tank Systems for Refrigerated Liquids) and API 650 (Welded Tanks for Oil Storage), reflecting new data on materials performance in ultra-low temperatures. Changes in 2025 emphasize enhanced leak detection and containment requirements, as well as updated guidelines for emergency venting and insulation in gasification systems.

Internationally, the International Organization for Standardization (ISO) has advanced ISO 16924 and ISO 21009 relating to LNG fueling stations and storage systems, which apply to cryogenic gasification plants. In 2025, revisions focus on harmonizing safety distances, instrumentation, and operational protocols, particularly in multi-fuel terminals integrating both LNG and liquid hydrogen.

Electrotechnical and automation standards are also developing. The Institute of Electrical and Electronics Engineers (IEEE) is updating its standards for hazardous area classification and control systems used in cryogenic environments. The 2025 revisions to the IEEE 841 standard address electric motors in cryogenic service, targeting improved explosion protection and reliability.

Looking forward, regulatory agencies such as the Pipeline and Hazardous Materials Safety Administration (PHMSA) are signaling tighter oversight on cryogenic facilities’ safety management systems and cybersecurity. As adoption of cryogenic gasification systems accelerates, the industry’s proactive engagement with standard-setting bodies is expected to further drive harmonization, enhance safety, and support the global shift to low-carbon fuels.

Supply Chain and Infrastructure Challenges

The commercial deployment of cryogenic fuel gasification systems is accelerating in 2025, driven by the rapid expansion of hydrogen and liquefied natural gas (LNG) markets. However, this growth is accompanied by significant supply chain and infrastructure challenges. Cryogenic gasification relies on the availability of ultra-cold storage, specialized transport logistics, and high-integrity materials, all of which face constraints as demand surges.

A primary bottleneck remains the global availability of cryogenic equipment, including storage tanks, vaporization units, and transfer pipelines. Leading manufacturers like Linde and Air Liquide have reported extended lead times for critical components due to elevated demand and ongoing disruptions in the supply of high-performance alloys and insulation materials essential for handling temperatures below -150°C. For example, Chart Industries has noted that orders for large-scale cryogenic vaporizers and modular gasification skids now routinely exceed 12-18 months for delivery, compared to less than a year pre-2022.

Transport infrastructure is another critical challenge. Cryogenic fuels require dedicated tanker fleets, pipelines with advanced insulation, and specialized port facilities. The expansion of global hydrogen shipping, expected to reach over 12 million tonnes annually by 2026, is straining existing logistics networks (Shell). Ports across Asia and Europe are investing heavily in new cryogenic terminals, but construction delays and regulatory hurdles have slowed progress. For instance, Uniper has faced delays in commissioning its new LNG import terminal in Germany due to supply chain issues and regulatory reviews.

Safety and standards compliance also present obstacles. The handling of cryogenic gases requires strict adherence to international codes (such as ISO 21009 and ISO 16924). Shortages of certified personnel for system installation, maintenance, and inspection are reported by industry bodies such as Hydrogen Council, potentially increasing project risks and costs.

Looking forward, industry leaders are investing in digitalization and supply chain transparency to mitigate these risks. Companies are expanding collaborations with steel and component suppliers, while also pursuing modular system designs to reduce on-site construction times (Linde). However, until new manufacturing capacity and infrastructure are fully online, intermittent shortages and logistical bottlenecks are expected to persist into the late 2020s.

Sustainability and Environmental Impact Analysis

Cryogenic fuel gasification systems are gaining traction as a pivotal technology in the transition toward cleaner energy and reduced greenhouse gas emissions. As of 2025, these systems—primarily used to convert liquefied natural gas (LNG), liquid hydrogen, or other cryogenic fuels into gaseous forms for power generation or industrial processes—are under increasing scrutiny for their sustainability profiles and environmental impacts.

A notable sustainability advantage of cryogenic gasification is its capacity to support low-carbon or zero-carbon fuels such as hydrogen. In 2024, companies like Linde and Air Liquide have expanded their cryogenic infrastructure to enable both the liquefaction and regasification of hydrogen, supporting the growing deployment of hydrogen in mobility and heavy industry. The use of hydrogen, when produced via renewable-powered electrolysis, results in near-zero emissions during end-use combustion, providing a strong environmental case for further rollout of cryogenic gasification systems.

Environmental impact assessments from operators such as Shell indicate that integrating cryogenic gasification with carbon capture and storage (CCS) can dramatically lower the lifecycle emissions of LNG-to-power projects. For example, Shell’s ongoing projects in Asia and Europe are deploying advanced regasification units capable of energy recovery, reducing both fuel consumption and associated CO2 output compared to conventional systems. This trend is expected to intensify through 2026 as regulatory pressures mount for lower-emission energy infrastructure.

Another key sustainability consideration is the energy efficiency of cryogenic gasification. Technologies developed by Chart Industries and Mitsubishi Power incorporate waste heat recovery and cold energy utilization—using the extreme cold from LNG vaporization to chill data centers or industrial processes. Such integration not only maximizes resource efficiency but also reduces overall thermal pollution and grid energy demand.

Looking ahead, the outlook for the environmental performance of cryogenic fuel gasification systems is positive. Industry investment is growing in modular, highly automated regasification platforms with digital controls for emissions monitoring and process optimization. The 2025–2028 period is likely to see wider adoption of hybrid systems—combining renewable energy, cryogenic gasification, and CCS—especially in regions targeting aggressive decarbonization. As technological improvements continue, and as lifecycle emissions accounting becomes more robust, cryogenic fuel gasification is positioned to play a critical role in sustainable energy supply chains worldwide.

Future Outlook: Investment Opportunities and Strategic Recommendations

Cryogenic fuel gasification systems are increasingly recognized as a cornerstone technology for decarbonizing industrial processes and power generation, leveraging liquefied natural gas (LNG), hydrogen, and even ammonia. As of 2025, several global initiatives and investments are reshaping the sector, with a pronounced focus on advancing system efficiency, scale, and integration with renewable energy sources.

Key players such as Air Products and Chemicals, Inc. and Linde plc continue to invest heavily in cryogenic technology to enable cleaner fuel production. For example, Air Products is building the world’s largest green hydrogen facility in NEOM, Saudi Arabia, set to become operational by 2026, deploying advanced cryogenic gasification and liquefaction processes to support global hydrogen supply chains. Similarly, Linde is expanding its portfolio of cryogenic plants in Europe and Asia, targeting the production of low-carbon fuels for both mobility and industrial sectors.

The growing adoption of LNG as a transition fuel is driving demand for efficient cryogenic regasification and gasification infrastructure. Woodside Energy is developing new LNG import terminals in Asia-Pacific, integrating next-generation cryogenic handling systems to minimize emissions and energy losses. In parallel, Siemens Energy is investing in digitalized cryogenic controls, promising up to 10% energy savings and enhanced operational reliability for gasification plants commissioned from 2025 onward.

Looking forward, the convergence of cryogenic gasification with carbon capture and storage (CCS) technologies is seen as a strategic investment theme. Shell has announced pilot projects in the Netherlands and Canada that combine cryogenic hydrogen production with integrated CCS, aiming to demonstrate scalable pathways for net-zero fuels. Moreover, Japan’s JERA Co., Inc. is piloting ammonia-based cryogenic gasification for power generation, with plans for commercial deployment by 2027.

Strategically, stakeholders are encouraged to focus on:

- Investing in modular cryogenic gasification units to enable flexible deployment and reduce CAPEX risk;

- Pursuing partnerships with renewable energy and CCS providers to maximize decarbonization potential;

- Leveraging digitalization and automation for efficiency gains and predictive maintenance;

- Targeting regions with robust policy support for hydrogen and low-carbon fuels, such as the EU, East Asia, and North America.

In summary, 2025 marks a pivotal year for cryogenic fuel gasification systems. Active investment, technological innovation, and strategic collaborations are expected to accelerate commercialization and unlock new value streams in the transition to a low-carbon energy future.

Sources & References

- Air Liquide

- Linde

- Shell

- Siemens Energy

- Linde plc

- KBR

- IHI Corporation

- TotalEnergies

- CNOOC

- GE Vernova

- Wärtsilä

- Siemens Mobility

- American Society of Mechanical Engineers (ASME)

- American Petroleum Institute (API)

- International Organization for Standardization (ISO)

- Institute of Electrical and Electronics Engineers (IEEE)

- Hydrogen Council

- Woodside Energy

- JERA Co., Inc.